Dale Burgess of ALLi Partner Print2Demand talks us through bookbinding technology

To help indie authors understand the binding options when ordering print-on-demand runs for their self-published books , Dale Burgess of ALLi Partner Member Print2Demand provides a guide to the different binding techniques now available and their pros and cons.

Three kinds of book binding are commonly used in the production of paperbacks:

- Thread sewn

- Perfect binding

- Polyurethane reactive adhesive (PUR)

A new arrival on the scene offers a fourth approach:

- Planamelt

Thread Sewn Binding

Thread sewn binding uses multiple threads to sew the signatures together. ( A signature is a group of pages printed on both sides of a sheet of paper.) The thread appears in the middle of a signature, and the books are much more durable and lay flatter than perfect or PUR bound books. This is the best binding method available, but needn’t be prohibitively expensive: investment in the very latest sewing machinery has enabled Print2Demand, for example, to offer thread-sewn binding at a cheaper price than PUR.

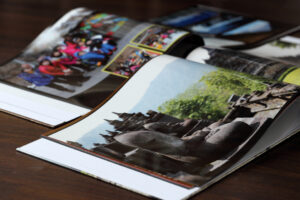

Samples of sewn hardback books

Perfect Binding

Perfect binding is a widely-used soft cover book binding method in which the pages and cover are glued together at the spine, using EVA hot melt glues.

Perfect-bound paperbacks from a print-on-demand run

Polyurethane reactive adhesive (PUR)

PUR is similar to perfect binding but uses a different kind of adhesive more suitable for digitally printed papers. Whereasthe conventional EVA hot melt glues used in perfect binding struggle with digital printed papers, with glossy papers and especially with finishing oils used in the process, PUR offers a strong highly flexible bind on almost any kind of material. The advent of PUR effectively allowed the printing industry to transition to the digital print technology required for print-on-demand runs.

The downside is that PUR is relatively expensive, particularly when unused glue has to be thrown away. The specialist application equipment is costly and needs attention because of the aggressive nature of the product, and ideally books should be left to cure before further finishing, adding waiting time to the production process.

Planamelt

The recent arrival of a new gluing system called Planamelt, a much more powerful hot melt adhesive than PUR, has revolutionised the PUR process by offering PUR’s advantages over perfect binding but without introducing the disadvantages that PUR creates, or any other drawbacks.

Planamelt is the most exciting breakthrough in glue technology for a generation due its unique bookbinding strength.

Print2Demand is one of ALLi's trusted Partner Members

Books bound with Planamelt can be handled after an hour, though it will take up to 24 hours to go off completely. This makes the production process is much faster than with PUR. Its advantages over perfect binding using standard EVA product include greater latitude in temperatures at which the glue works and greater resistance to solvents. This is even better than the new generation of micro-emission PURs, where there can be adverse reactions to plasticisers in inks, or where there is a limited cure on very dry papers.

First launched in 2015, Planamelt binding is now available at Print2Demand and other suppliers around the world, offering a viable, affordable and swift fourth alternative to the three longer-established methods outlined at the beginning of this post.

Bookbinding techniques explained for #indieauthors using #printondemand for their #selfpub books Share on XOTHER HELPFUL POSTS ABOUT BOOK PRODUCTION

From the ALLi Author Advice Center Archive

Thanks for the article!

This was very informative! Thank you for explaining these different forms of printing to us!